The trial use of Kluberfluid C-F 3 Ultra on some coal mills at the Mong Duong 2 Thermal Power Plant has achieved very good results, leading to the product being used to lubricate all the coal mills of the plant. After nearly 5 years of operation, the gear pairs are still in very good condition, and the coal mills are operating stably.

Mong Duong 2 Thermal Power Plant was built in 2015 in Mong Duong Ward, Cam Pha City, Quang Ninh Province. It is a 100% foreign-owned company in the form of a BOT with a total investment of around $2 billion. The total power generation capacity of the two turbine units is 2 x 621 MW.

The plant has 12 ball mills driven by open gear rings. Initially, the plant used a black grease with an asphalt base for the automatic lubrication system of the gear rings. After a short period of operation, it revealed the following drawbacks that significantly impacted the coal mill operation:

- Frequently caused clogging of the grease spray nozzles.

- High grease consumption.

- The black color of the grease made it difficult to inspect the gear condition and clean the used grease, as it became hardened.

After surveying the open gear rings and discussions with the plant, on April 14, 2017, Vu Minh Company began supplying the Kluberfluid C-F 3 Ultra for trial use on some of the coal mill open gear rings. At the end of the trial period, the Mong Duong 2 Thermal Power Plant highly evaluated the Kluberfluid C-F 3 Ultra. The outstanding advantages of Kluberfluid C-F 3 Ultra compared to the black grease with an asphalt base:

- Kluberfluid C-F 3 Ultra has a high viscosity base oil of 16,500 cSt, providing good adhesiveness.

- It forms a thick lubricating film, enhancing the protection of the gear surface.

- The light-colored grease makes it easier to inspect the gear condition.

- Kluberfluid C-F 3 Ultra does not clog the spray nozzles as it does not contain solid lubricating particles.

- It reduces grease consumption by around 50% compared to the previous black grease.

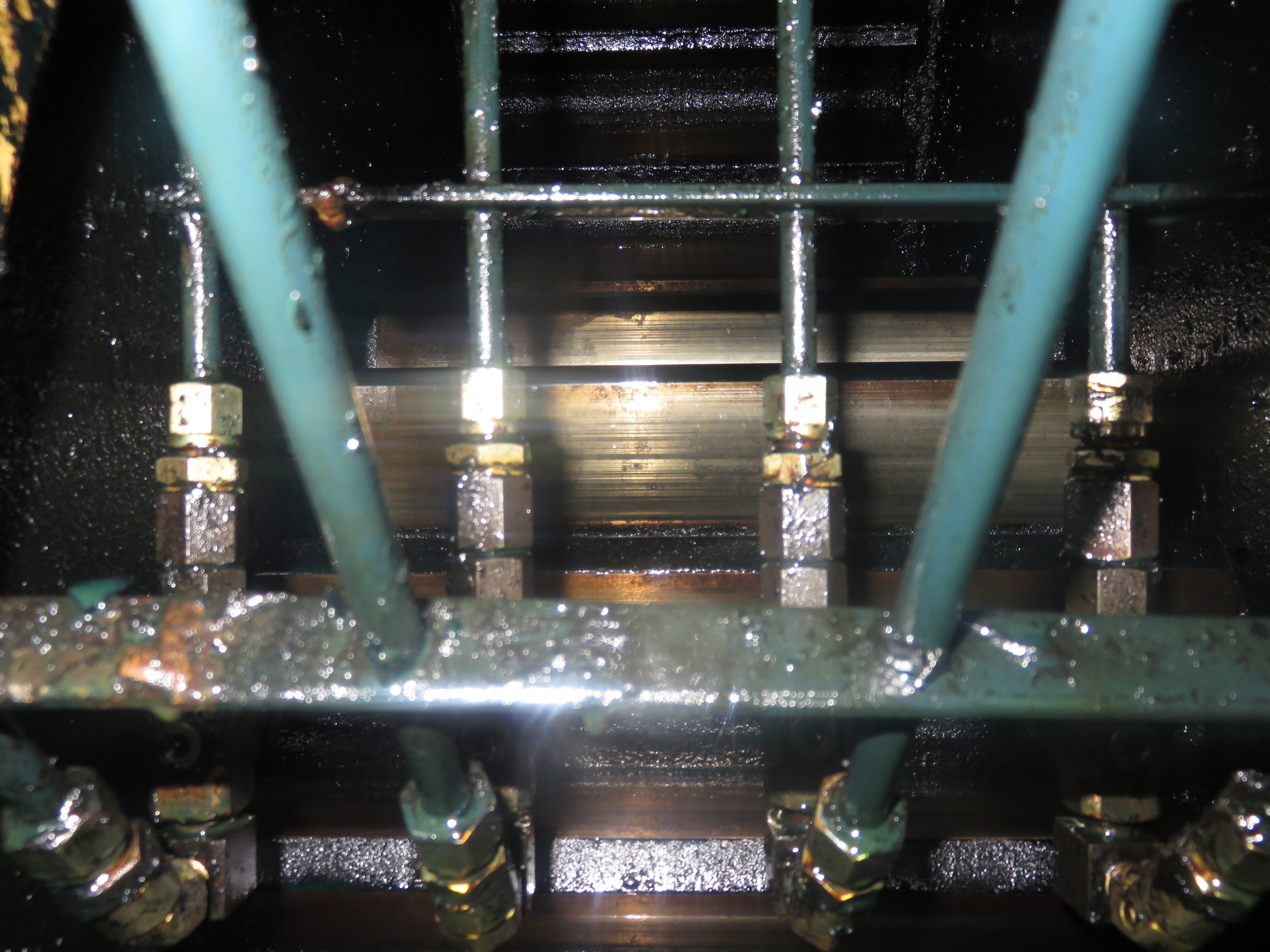

After the successful trial of using Kluberfluid C-F 3 Ultra on some coal mills, it has been used to lubricate all the coal mills at the plant. After nearly 5 years of operation, the gear sets are still in very good condition, and the coal mills are operating stably. Some of the results observed are:

- Minimal gear tooth wear, maintaining the original gear profile.

- Shiny gear surface.

- No pitting on the gear surface.

- Easy to recover and reuse the spent grease, reducing waste treatment costs.

The open gear sets on the coal mills being in such excellent condition is the result of the plant's extremely good and professional operation and maintenance processes, and it confirms the superior performance and market-leading quality of the Kluberfluid C-F 3 Ultra.

The condition of the pinion (small gear) remains in very good condition after using the Kluberfluid C-F3 Ultra.

Vu Minh engineer inspects the open gear set.